Flexible packaging is widely used in various industries, from food and beverages to healthcare, cosmetics, etc. The market size of flexible packaging is growing at an annual rate of 6.2% and is expected to exceed US$300 billion by 2030.

As a professional flexible packaging manufacturer, I will discuss with you the factors behind the growth in demand for flexible packaging and analyze its market potential.

Cost-Effectiveness and Efficiency

Flexible packaging is often more cost-effective than traditional rigid packaging materials such as glass or plastic. The production of flexible packaging requires fewer raw materials and less energy, making it a more efficient option for manufacturers.

In addition, the lightweight nature of flexible packaging reduces shipping and transportation costs, making it a top choice for many businesses looking to minimize logistics expenses.

Advancements in Packaging Technology

The flexible packaging industry has witnessed great technological advancement. Improvements in materials, printing, and sealing technologies have made flexible packaging more durable, functional, and appealing.

For example, the development of high-barrier films and multilayered structures has enhanced the ability of flexible packaging to preserve product freshness while providing protection from moisture, oxygen, and light.

- High-Barrier Films: These films prevent the infiltration of moisture, oxygen, and light, ensuring that the product remains fresh for a longer period, particularly for food and pharmaceutical products.

- Enhanced Durability: Technological advancements in flexible packaging materials, such as stronger laminates and seals, make packages more resistant to punctures, tears, and leakage.

- Multi-Layer Construction: Multiple layers of material are used in flexible packaging to provide different functions, such as enhanced protection, strength, and ease of handling, all while maintaining lightweight characteristics.

Technologies such as green coatings, better graphics printing, and customization have also allowed companies to create packaging that is functional and attractive. The ease with which companies can tailor flexible packaging to meet branding and consumer demands has fueled its popularity across most industries.

- Eco-Friendly Coatings: With a focus on sustainability, eco-friendly coatings, such as water-based or solvent-free coatings, are used to reduce environmental impact while maintaining the quality of packaging.

- Advanced Printing Capabilities: High-quality, full-color digital printing allows brands to create visually stunning packaging that stands out on retail shelves and online marketplaces.

- Customization and Personalization: Brands can create limited-edition designs, seasonal packaging, or customer-specific packages with ease, making packaging a key part of their marketing strategy.

Growing Focus on Sustainability

Sustainability ranks high on the agenda of consumers and businesses alike. Flexible packaging offers several sustainability advantages over traditional packaging materials. For one, the majority of flexible materials are lighter in weight, which reduces the environmental impact during transportation. In addition, innovations in recyclable and biodegradable materials are making flexible packaging increasingly attractive to environmentally conscious consumers and businesses aiming to achieve sustainability goals.

- Lower Carbon Footprint: Flexible packaging’s lightweight nature reduces transportation costs and emissions, contributing to lower carbon footprints compared to heavier packaging materials.

- Eco-Friendly Materials: Advances in sustainable materials, such as biodegradable plastics, plant-based resins, and recyclable films, are enabling companies to meet environmental goals without compromising on performance.

- Recycling Potential: Many flexible packaging materials are designed to be recyclable or biodegradable, making them a more eco-conscious choice for both brands and consumers.

Food and Beverage Industry Growth

Food and beverage is one of the largest consumers of flexible packaging, and the trend is showing no signs of slowing. With the consumer looking more and more for packaged, ready-to-eat, or convenient foods, flexible packaging is well placed to deal with these products. Snack foods, beverages, frozen foods, and processed meals, particularly in the developing economies, are leading demand for flexible packaging solutions.

- Convenience and Portability: Flexible packaging is particularly attractive to consumers looking for convenience meal solutions on the move, such as snack packs, ready meals, and single-serve drinks.

- Extended Shelf Life: Technological innovation in barrier films and vacuum sealing technologies extends the shelf life of perishable food products, reducing food wastage, and giving consumers confidence that they can access fresh products.

- Global Expansion: Flexible packaging solutions find special relevance in emerging markets, where they deliver cost-effective and space-saving packaging solutions to meet growing demand for packaged food.

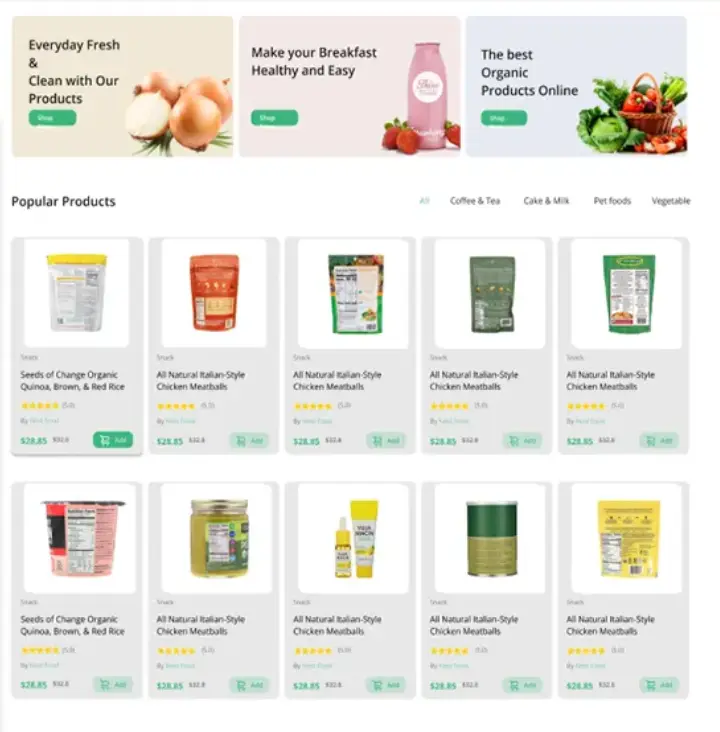

Flexible packaging not only extends the shelf life of food products but also enhances product visibility with vibrant, eye-catching graphics. The growing trend of e-commerce in food and beverages also plays a role in the rising demand for flexible packaging, as it allows products to be delivered more efficiently.

- Branding and Consumer Appeal: The ability to print vivid, high-quality graphics on flexible packaging helps brands create packaging that attracts consumers’ attention, especially in a crowded retail market.

- E-commerce Convenience: Flexible packaging’s compact size and durability make it ideal for food products sold online, reducing packaging waste and improving the shipping process.

- Product Differentiation: Unique, customizable packaging helps food and beverage brands stand out, increasing consumer interest and brand loyalty.

E-commerce and Online Shopping

As e-commerce continues to thrive, packaging solutions that can protect products during transit while also being cost-effective have become increasingly important. Flexible packaging meets these criteria by providing durability, tamper-evidence, and ease of handling during shipping. Since flexible packaging is lightweight and compact, it is easier and cheaper to ship than rigid packaging, reducing shipping costs for online retailers and making it an attractive option for products sold through e-commerce platforms.

- Protective Features: Flexible packaging can be designed with tamper-evident seals and durability enhancements to protect products during transit, ensuring safe delivery.

- Shipping Efficiency: Because of its lightweight and compact nature, flexible packaging reduces shipping costs, which is especially important for e-commerce retailers aiming to maintain competitive pricing.

- Customizable Solutions: E-commerce businesses can tailor flexible packaging to fit specific products and shipping requirements, offering a tailored experience to customers.