Packaging is the comprehensive embodiment of brand image, product protection and user experience. When choosing a packaging solution, enterprises are often faced with a choice between “flexible packaging” and “rigid Packaging”. This article will compare the two from many aspects to help enterprises choose the most suitable packaging solution.

1. Flexible Packaging vs. Rigid Packaging: Basic Concepts

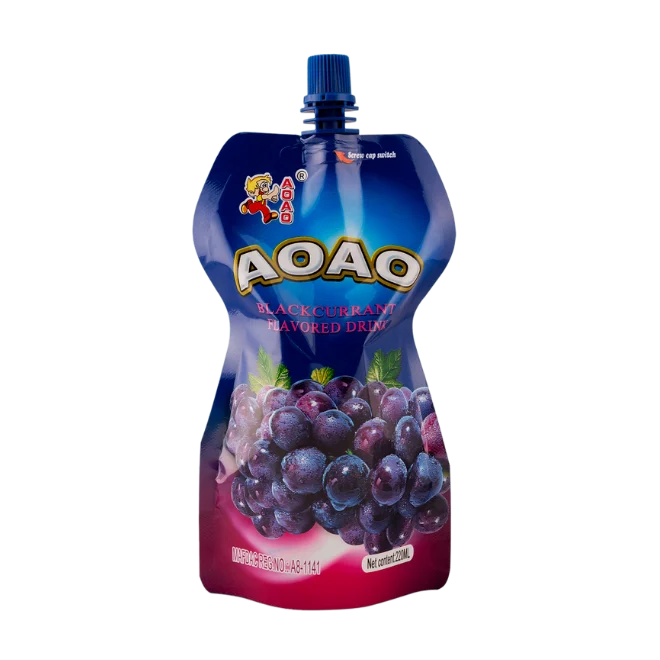

Flexible Packaging: Made of flexible materials such as plastic film, aluminum foil, paper, etc., flexible packaging has the characteristics of being lightweight, foldable, and customizable, and the common forms include stand-up pouches, spout pouches, shrink sleeves, packaging film rolls, etc.

Rigid packaging: It is made of rigid materials such as glass, metal, hard plastic, and cardboard, and is usually used in bottles, cans, boxes and other packaging methods with stable structure.

2. Flexible packaging vs. rigid packaging: features

1. Production cost and transportation cost

Flexible packaging has advantages in terms of production costs and transportation costs. Because they are made of plastic film, aluminum foil or composite materials, less material is required and the production process is simpler than rigid-packed glass, metal or thick plastic. In addition, flexible packaging can be folded for storage, which takes up little space, effectively reducing logistics costs during transportation.

In contrast, rigid packaging typically requires processes such as mold making, injection molding, blow molding, or metalworking, and is more expensive to produce. At the same time, rigid packaging is bulky and heavy, taking up more space during transportation, resulting in increased logistics costs, especially in global supply chains.

Conclusion: Flexible packaging has more advantages in cost control and logistics efficiency, and is suitable for enterprises that pursue cost-effectiveness.

2. Environmental protection and sustainability

Environmental protection has become an important consideration for the packaging industry, and flexible packaging has obvious advantages in reducing carbon emissions and the use of materials. Flexible packaging consumes fewer resources in the production process and is lightweight, helping to reduce energy consumption during transportation. In addition, with the development of degradable and recyclable flexible packaging materials, the potential of flexible packaging in the field of environmental protection continues to increase.

Comparatively, rigid packaging has certain advantages in terms of recyclability. For example, glass bottles and metal cans can often be recycled. However, its production process consumes more energy and has a larger carbon footprint, which is not conducive to environmental sustainability. As a result, more and more companies are looking for more environmentally friendly packaging alternatives.

Conclusion: In terms of environmental protection, flexible packaging is more favored because of its lightweight and low carbon emissions.

3. Design flexibility

Flexible packaging offers more design and branding flexibility. It can employ high-definition printing technology to achieve rich colors and patterns to make products more attractive on the shelf. At the same time, flexible packaging supports a variety of forms of customization, such as stand-up pouches, spout pouches, shrink sleeves, etc., which can meet the packaging needs of different products and enhance the personalized display of the brand.

In contrast, the design of rigid packaging is limited by mold manufacturing, which is difficult to change once molded, and the cost of customization is high. In addition, the printing area of rigid packaging is relatively limited, and the space for brand promotion is small. Therefore, flexible packaging is a better choice for enterprises that want to strengthen their brand image and enhance their market competitiveness through packaging.

Conclusion: Flexible packaging has higher flexibility in design and is more suitable for the highly competitive consumer goods industry.

4. Ease of use

Modern consumers attach great importance to the convenience of packaging, and flexible packaging stands out in this regard. For example, spout pouches can be easily opened and closed to avoid liquid leakage; Stand up pouches can be used directly without additional containers, improving the user experience. In addition, the flexible packaging is lightweight and easy to carry, making it ideal for outdoor, travel, and other use scenarios.

In contrast, rigid packaging is a little less convenient in terms of convenience. Packaging methods such as bottles and cans tend to be heavier, less easy to carry, and may not be flexible enough when opening and pouring contents. For modern consumers who pursue lightweight and convenience, flexible packaging is more in line with market trends.

Conclusion: Flexible packaging is more convenient, in line with the pursuit of modern life, and the user experience is better.

| cost | Environmentally friendly | Design flexibility | Convenience | |

| Flexible packaging | Lower | In line with environmental trends | Flexible and diverse | Great |

| Rigid packaging | Higher | Not good for sustainability | Limited to the ontology | Slightly insufficient |

3. How do companies choose the best packaging solution?

When choosing a packaging solution, enterprises need to consider it comprehensively based on product characteristics, market demand and brand positioning. Here are a few key decision points:

Product characteristics: If the product needs to be stored for a long time, crush-resistant or shatter-proof, rigid Packaging is more suitable; If you are looking for lightweight, convenience and tightness, flexible packaging is the best choice.

Target market: If the product is sold on the supermarket shelf, the display effect of the packaging needs to be considered; If the sales are mainly through e-commerce, the lightweight packaging and transportation costs become the focus.

Environmental requirements: If companies want to adopt sustainable packaging, degradable materials or recyclable technology for flexible packaging is an important direction.

Budget and production scale: The production cost and transportation cost of flexible packaging are low, which is suitable for enterprises pursuing cost control and large-scale production.

4. Guoqiang’s flexible packaging solutions

As a professional flexible packaging manufacturer, we provide high-quality, environmentally friendly and innovative packaging solutions to help brands enhance their market competitiveness.

High-quality materials: Food-grade materials are used to ensure safety, and provide a variety of functions such as moisture-proof, anti-oxidation, and anti-ultraviolet rays.

Customized service: Supports high-definition printing, personalized packaging design to meet the needs of brand promotion

Environmental sustainability: Provide recyclable and degradable packaging solutions to help enterprises achieve green packaging goals.

Cost-effective: The production cycle is short, the cost is relatively low, suitable for mass production, and the logistics and transportation costs are reduced.

Conclusion

Flexible packaging and rigid Packaging have their features, enterprises should choose the most suitable packaging solution according to their own needs. With its advantages of lightweight, environmental protection and convenience, flexible packaging is widely used in food, daily chemical, pharmaceutical and other industries. If you are looking for high-quality flexible packaging solutions, we can provide you with professional customized services. Welcome to contact us to learn more about flexible packaging solutions!

Contact Us

Don't hesitate to call usgqpackaging@gmail.com

Don't hesitate to contact usAnbu Longkeng Xipu Industrial Zone, Chaozhou, Guangdong, China